Tag: bodyforce

765 Pound Barbell Drop Test!

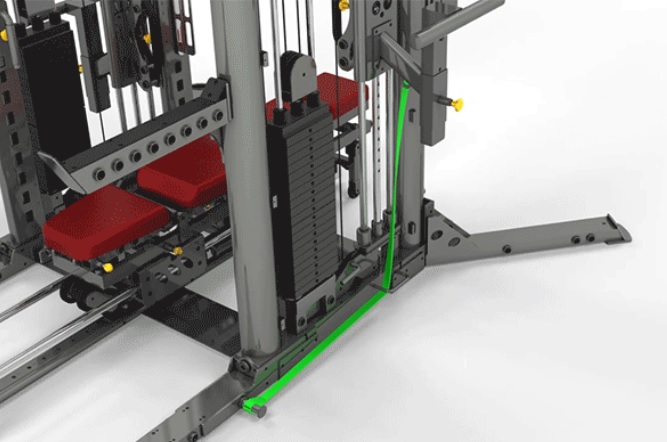

You can do all the Finite Element Analysis (FEA) tests you want (at Bodyforce we have done plenty) but at the end of the day you need to test your product in a real world environment to see what it’s truly made of. This is where “the rubber meets the road” so to speak. In that vein please see below where we perform two barbell drop tests on our X9 Evolution Hybrid Gym.

To perform these tests we loaded a standard Olympic barbell with as many plates as it could hold (16 x 45 LBS plates). This, plus the weight of the bar (45 LBS), totaled 765 LBS. We tried to create a “worst case scenario” by using the cheapest plate holder “spring clips” we could find. We postulated that the heavy load combined with extreme angles (bent parabola shape) of the barbell when fully arrested at the bottom of its drop, would force the springs off causing an imbalance of plates on the bar. This is precisely what happened.

In this first video the bar falls nearly 3 feet. We used this height to simulate an NBA basketball player who is approximately 6’10” inches tall dropping the barbell directly from his shoulders at the top of a squat simulating a worst case scenario. For this test we also used an X9 frame that had only been “tack welded” giving it a fraction of its normal full welded strength, again a worst case scenario. As you can see the X9 still handled the drop without breaking a sweat. The barbell was not so lucky. It was bent beyond repair.

A couple quick take aways from the video:

- Cheap spring clips do a poor job of keeping weight plates secured on the barbell and are not recommended.

- Even with heavy duty safety spotters, if the collars come off you are quickly in an asymmetry situation where the bar wants to fall off to one side.

- The initial impact was easily and effectively absorbed by the X9.

Now lets take a look at the second drop test using our patent pending Bodyforce spotting system which combines the X9’s heavy duty safety spotters with our TuffStich 10,000 LB looped spotter straps. Watching this video you will again see the weight plate “collar springs” quickly ejected from the barbell and yet the system contains the barbell safely and completely. Even if more weight plates came off one side and you were laying unconscious on the floor you would be fully protected. This is due to the strap systems ability to “cradle” the barbell giving it not only vertical control, but horizontal control in all directions as well. To learn more about our robust spotting system please check out the X9 product page. Our safety strap system is not only good at containment but very functional with “on the fly” height adjustments as well.

Take aways from the second video:

- The safety spotting system completely contained the barbell left/right, front/back and vertically.

- With the weight more evenly distributed, less total stress is put on any one part. Side load on safety spotters is almost fully eliminated.

- Something else worth considering; If you drop a barbell more than about one foot onto a safety spotter that utilizes plastic covering on top, there’s a good chance that surface will become damaged. If you typically lift to failure, dropping your weights onto safety spotters, it won’t take long to chew the plastic covers up. These covers are there to protect your barbell knurling from damage not the other way around. With the Bodyforce spotting system you have the best of both worlds; protect the bar and plastic with the best spotting system on the market. If you want to double your peace of mind you can use a set of spotters with the Bodyforce safety strap system above while locking in a secondary set of spotters down low. Either way you will be 100% protected.

For some related subjects please see:

Power Rack and Half Rack

Safety Spotters

Gauge

Hole Spacing

Band Work Is Not Just for Barbells Anymore.

Not about Market Share.

At Bodyforce we designed the X9 to start as a basic (albeit premium) free weight platform. From there the customer has the ability to tailor-make it to their desired budget and requirements.

We currently have over 30 options ready or in the pipeline. Different options will appeal to different people depending on their objectives. We will likely continue to create more options based upon user feedback and recommendations. When you buy some “all-in-one” machines, you end up paying for things you may not be interested in. We are “unbundling” as many parts (big and small) as we can so you only pay for what you want. As an example, some people may already own an adequate cable system or bench. We don’t want to force them into buying those items if they don’t want/need them. That said, our system is designed to work in concert with all of it’s parts so admittedly pairing our options with our machine does have some advantages.

A person can start with the basics now and as their needs/budget increase, add more options later. We have worked hard to “future proof” the design so the attach points remain consistent. Other companies want you to buy entirely new products every few years and don’t worry about future proofing. In fact, they typically stand against this concept for increased revenue and market share to support their multiple layers of management/overhead, etc. We could care less about market share and just want to sell one amazing machine to each customer once, supporting them with as many options as they desire over a lifetime.

Ignore the Hype.

Ever been flipping through the channels late at night and run into a fitness company making outrageous claims?…. “With our system in 3 weeks you will have the body of a top athlete!” Or have you ever heard claims of a gym system that “offers 200+ exercises”. Yes, technically, if you get really creative you might be able to squeeze 200 mostly ridiculous exercises out of these products, but after further scrutiny you realize most of those exercises are absolutely useless. At Bodyforce our products are designed with more capability than any products on the market. Real capabilities and real, useful exercises.